PAC PERFORMANCE-BASED TESTING SERVICES

FOR CLIENTS NATIONWIDE

Our goal at EPS is to help the water treatment industry optimize its activated carbon selection by providing Performance Factors – developed specifically for each utility or company. These performance factors allow our customers to make an informed decision on activated carbon based on cost per unit of MIB (or other compound) removed, as opposed to cost per unit weight. In this industry, quality is more important than quantity, and a decision based on test results can save tens of thousands of dollars on activated carbon.

Activated carbon is specially processed to maximize its surface area to volume ratio through a multitude of small pores. This makes it particularly useful for filtering contaminants out of water. Powdered activated carbon, or PAC, is even finer, consisting of particles that have been ground or crushed. Many water treatment plants add it into the water supply at various points of the treatment process in order to control taste and odor. Not all PAC is created equal, however, which is where our professional activated carbon testing services come in. Engineering Performance Solutions is a trusted carbon testing company serving commercial vendors, engineering firms, and municipal utility companies across the nation. Enlist the aid of our high-quality powder activated carbon services to determine the ideal type of carbon for your specific usage.

Contact us today to learn more about our carbon performance-based test and schedule an appointment with a member of our team!

Performance Factors

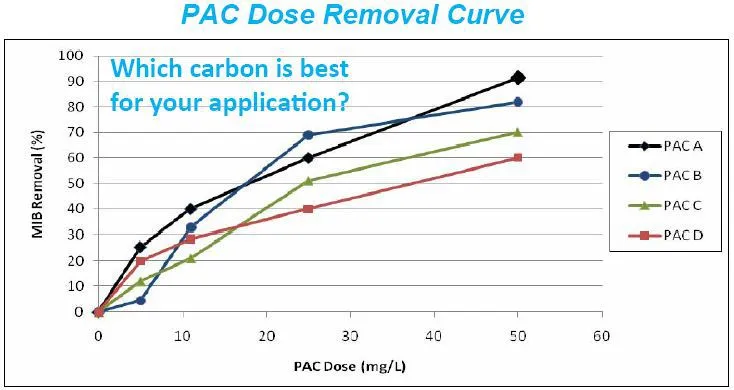

EPS will develop multi-point dose removal curves using several PACs for a contaminant of concern. This data allows clients to choose the optimum PAC for their application based on price and performance as well as predict doses needed to meet treatment objectives. As the figures below demonstrate, excessive amounts of money can be spent on treatment chemicals that were chosen based on price, without considering performance.

PAC Dose Removal Curve

Performance Factor Example

| PAC | Dose (mg/L) Required to Achieve 60% MIB Removal’ | Performance Factor | $/Ton | Adjusted $/Ton |

| A | 25 | 1.1 | 1300 | 1430 |

| B | 22 | 1.0 | 1360 | 1360 |

| C | 37 | 1.7 | 1450 | 2465 |

| D | 50 | 2.3 | 1160 | 2668 |

1 60 percent MIB removal was chosen for demonstration purposes only

A Performance Factor gives a “weighted ranking” for the treatment chemical being tested. The optimal chemical is scored as a 1.0, and the less efficient chemicals are scored in relationship to the best performer (always receiving a higher factor). Multiplying the Performance Factor by the treatment chemical cost provides a weighted cost that incorporates both performance and economics. Without performance factors, utilities might purchase Carbon D at $1160/ton, which appears to be a value, but because of its poor performance, actually costs much more ($2668/ton) to achieve the same results as Carbon B at $1360/ton. That’s almost half the cost!

EPS believes that performance-based testing is the optimum method for determining which activated carbon is best for the particular application. Therefore, EPS performs all performance-based tests with the customer’s carbons and water in order to best mimic the conditions of the full-scale facility. Proper performance-based testing can alleviate overspending on treatment chemicals and help ensure all treatment goals are met.